In the field of building, accuracy and precision are crucial. The intricate dance of beams, columns, and connections when creating massive steel structures necessitates a degree of complexity that goes beyond the plan. Here is where steel detailing companies—the unsung heroes of construction—come into action. In this investigation of the unsung heroes of the construction industry, we dive into the realm of steel detailing, revealing the art and science of the painstaking planning and drawing that serves as the foundation for the development of magnificent structures and infrastructure. Join us as we explore the intricate details of steel detailing, where lines drawn on paper become the steel underpinning of our contemporary world. This blog is your behind-the-scenes access to the world of steel details, whether you’re an aspiring engineer, an inquisitive architect, or just someone fascinated by the magic behind skyscrapers and bridges. Together, let’s learn the secrets.

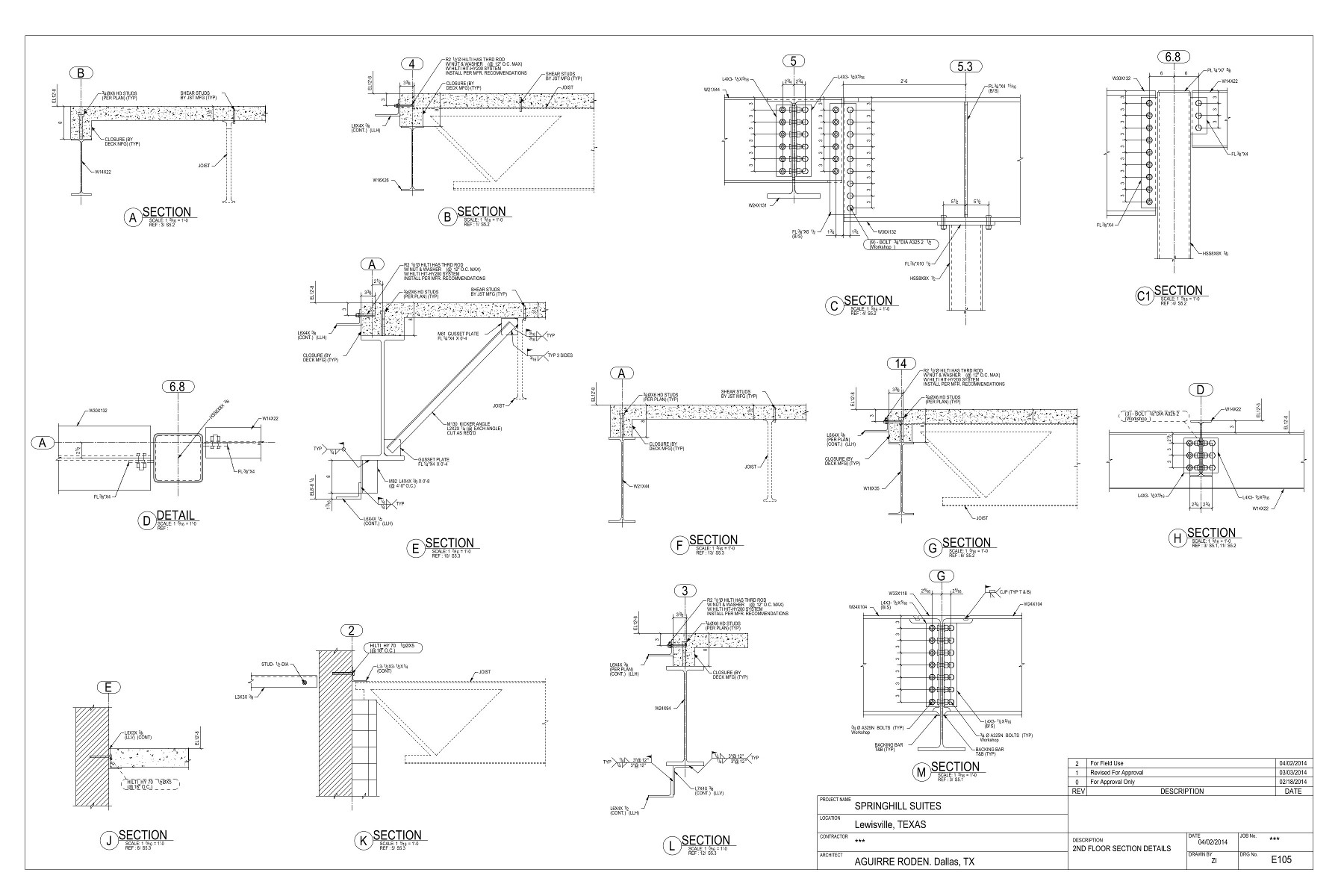

Creating thorough 2D and 3D drawings that provide a complete visual representation of the steel components and their exact dimensions is the basic service of structural steel detailing Companies. These blueprints serve as a guide for the construction process and are essential to maintaining the integrity and correctness of the finished product.

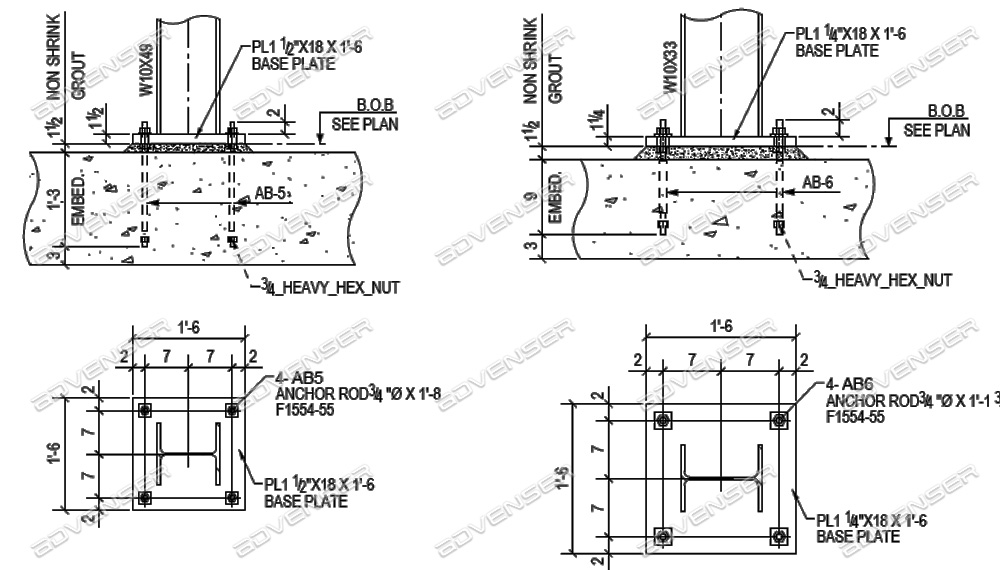

Shop drawings provide as a link between conceptual design and real-world production. They provide fabricators all the necessary information, such as material specifications, weld types, and assembly instructions, to build each steel component precisely and in compliance with project standards.

A steel structure’s safety and stability depend heavily on connection design. Structural engineers are used by steel detailing Companies to calculate forces and stresses, choose the best connection method (such as bolting or welding), and make sure connections are built to handle the desired loads.

Through the use of cutting-edge tools and skill, ESS Steel Detailing Services builds connections that are not only reliable but also cost-effective. We stand out because of our engineers’ commitment to perfection.

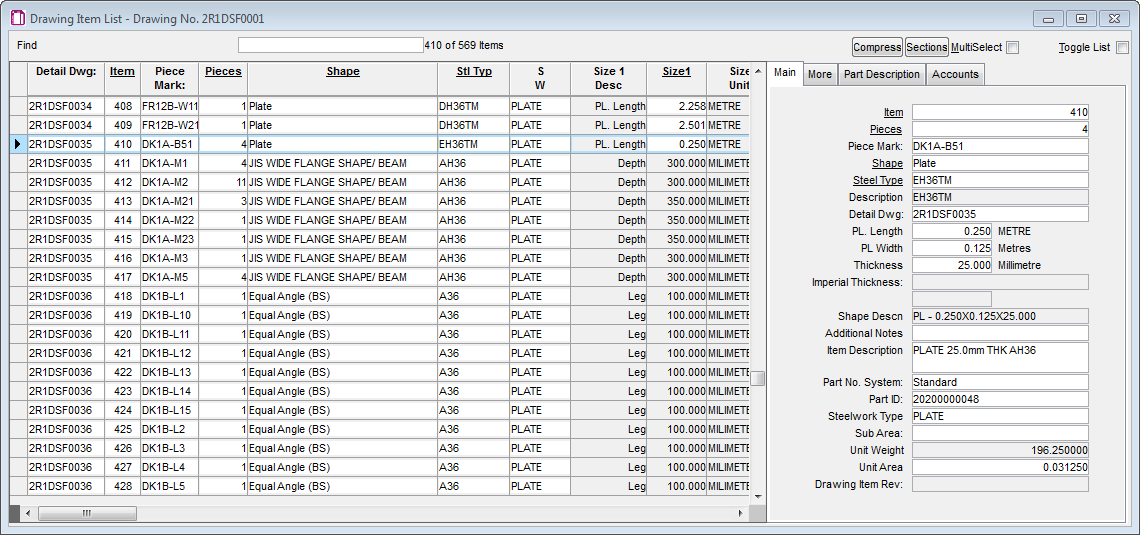

Material takeoffs are essential for cost assessment and procurement. A detailed inventory of all necessary materials, including their amounts and specifications, is provided by steel detailers. This thorough bill of materials (BOM) simplifies the purchase procedure and aids in project cost management.

We at ESS go above and above the norm. In addition to material takeoffs, we also offer thorough Bills of Materials, giving customers the knowledge they want for effective procurement and project cost management.

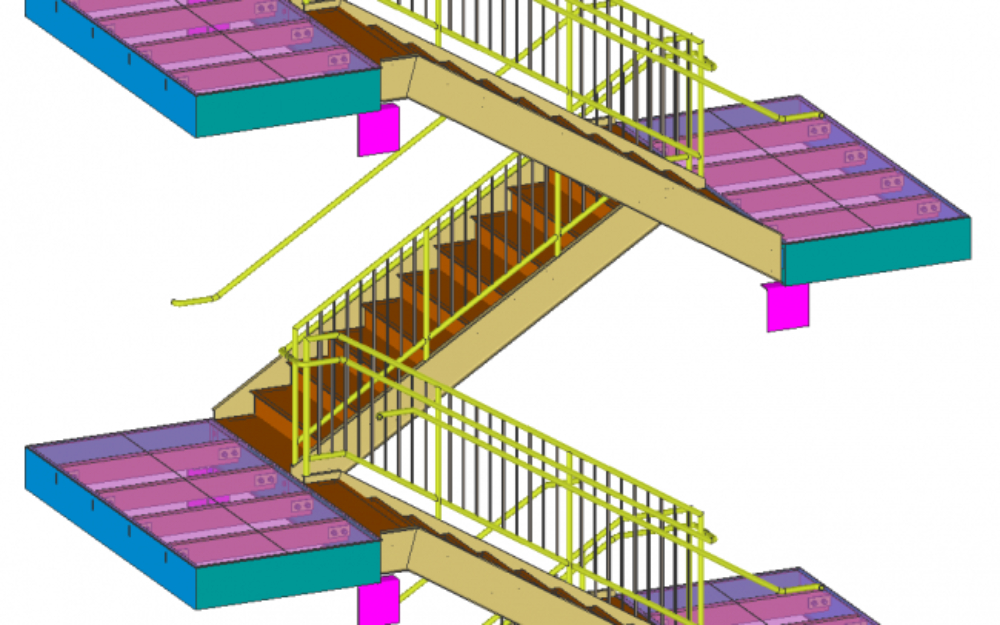

The construction team uses erection plans as a blueprint to assemble steel parts on-site. These blueprints, which are made by steel detailing firms and include details on crane positioning, the sequence of assembly, and safety concerns, guarantee an efficient and well-planned erection procedure. In addition to providing blueprints, ESS Steel Detailing Services also offers solutions for more efficient construction. We maintain projects on schedule and under budget with our rigorous erection plans that are carefully developed.

Steel detailing businesses offer the specialized service known as “Stair and Rail Detailing” to guarantee the secure and attractive design of stairs and railings within building projects. Using information on the number of steps, rise and run measurements, handrail extensions, material selection and compliance with building codes and safety standards, complete designs and drawings for stairs and railings are created as part of this service. Stair and rail detailing also takes into account the individualization and coordination needed to effortlessly incorporate these elements into the framework of the entire building.

.jpg)